As a Japanese manufacturer, HAKKO is at the forefront of soldering and desoldering equipment worldwide and is always at the cutting edge of technology.

HAKKO's innovative spirit has been demonstrated time and again over the last 20 years, both in the implementation of the current lead-free standard for solder, as well as in the introduction of new processes such as soldering under nitrogen, high power soldering and desoldering with 300 watts of power and with soldering tools for miniaturised components.

Hakko offers you:

- A complete range of high-quality and durable hand soldering technologies

- Innovative soldering technologies that are customised to meet the challenges of production in a solution-oriented manner

- Solutions for hot air soldering, soldering under nitrogen, soldering technology for miniaturised components, rework and repair technology, high-performance soldering and desoldering

- Outstanding product quality, durability, high reliability and service life of consumables such as soldering tips and nozzles

- Custom-made solutions on request for special nozzles or soldering tip formats

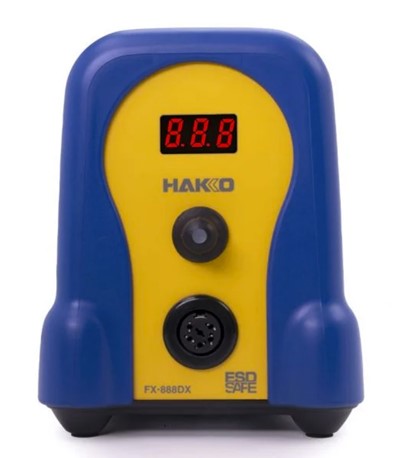

FX-888DX

Compact, digital all-round soldering station from Hakko. Hakko is known for the high quality of its products, which also applies to this soldering station. Digitalisation has enabled additional functions such as digital calibration, five adjustable presets and password protection (to prevent unwanted temperature overshoots in production or training environments). There are 6 different soldering irons/tweezers available, and N2 soldering can also be added.

FR-400

With its enormous heat output of 300 watts, the FR-400 enables the processing of previously almost impossible desoldering and soldering tasks on PCBs with high heat capacity and heat dissipation.

Desoldering printed circuit boards designed for high currents is becoming increasingly difficult with the current state of the art. The high heat capacity and heat dissipation of components and assemblies is typical of the high-resistance, low-voltage range. Sometimes it is necessary to work on the solder joints with two people, with one person melting the solder at the joints with the soldering iron while the other person extracts the solder from the other side. With the FR-400 desoldering station, this work can be done by one person. The FR-400 offers a significant improvement in the rework process of printed circuit boards designed for high currents.

FR-410

The FR-410 is the ideal station for desoldering micro soldering points or where space is limited. With an output of 140 W, the station enables perfect desoldering of components on multilayer PCBs.

Thanks to the valve function with high suction power and the optimised arrangement of the heating element, the FX-410 guarantees safe desoldering, as the solder remains liquid until it enters the filter. The large selection of desoldering nozzles, which can be changed easily and safely with a special changing tool or optionally with a non-contact quick-change device, enables a wide range of applications in which safe and efficient work is paramount.

The FR-410 offers a significant improvement in the rework process of PCBs with high component density for flat connectors or micro soldering eyes.

FR-810B

The Hakko FR-810B offers a powerful combination of high air volume and high heat output to remove components quickly and efficiently. The powerful hot air flow enables the repair of densely populated PCBs with high heat capacity. The air flow rate is so high that the work can be carried out in a third of the usual time. This significantly reduces the thermal load on the PCB and the components. In addition to the tried and tested functions, the Hakko FR-810B also has a vacuum lift-off function and a lift-off indicator. Both features enable components to be removed safely without damaging the PCB.

With its impressive performance and generous air volume, the Hakko FR-810B represents a further development in the field of SMD rework stations and is also the perfect tool for rework work.

FR-811

The compact Hakko FR-811 rework station combines all functions for precise SMD repair tasks in one device.

Equipped with a powerful hot air flow and a high heating capacity, the station enables the repair of PCBs with a high thermal capacity. It also offers sufficient air flow and a suitable hot air volume for processing PCBs with a high packing density. The FR-811 has intuitive menu navigation, which is shown on an easy-to-read LCD display. Parameters can be transferred directly or via USB stick via a USB interface. This enables simple monitoring and temperature adjustment in real time.

The lift-off indicator and the vacuum lift-off function enable the user to lift off even concealed components easily and safely.

Changing the nozzles and replacing the heating element for different components is quick and uncomplicated and makes working with the system extremely efficient.

FX-971

The HAKKO FX-971 1-port soldering station is a basic solution for most applications in electronics production.

Increased requirements in the soldering process have resulted in a compact and ergonomically optimised design with an output of 100W, significantly faster response times and an extended range of active soldering tips that guarantee performance that is among the best the market currently has to offer. A unique feature is the easy-to-read display, which can be swivelled with the station and shows the user all relevant process information.

To save energy, the soldering station is equipped with an adjustable auto-sleep function and automatic switch-off after a preset time. These functions also increase the service life of the soldering tips. The requirements for N2 shielding gas soldering are also well covered by this range.

FX-972

The HAKKO FX-972 2-port soldering station is a basic solution for most applications in electronics production.

The station is ideal for all types of repair processes and, in addition to the standard soldering iron, offers a micro soldering iron, a high-performance soldering iron and two different soldering tweezers to meet the requirements of massive solder joints or solder joints that require fast heat-up times. The FX 972 has an output of 200 W. The new generation of active soldering tips is capable of ensuring temperature changes or tracking the heating power with a performance that is among the best the market currently has to offer.

To save energy, the soldering station is equipped with an adjustable auto-sleep function and automatic switch-off after a preset time. These functions also increase the service life of the soldering tips. The requirements for N2 shielding gas soldering are also well covered by this range.

-400x300-White-b.jpg)